With diameters ranging from 0.6m to 3.6m, our steel navigation buoys can be used in inland rivers, lakes, and oceans. All steel plates are chosen from marine steel plates with hull thicknesses from 5 mm to 12mm, quite solidly.

Why Choose Our Steel Navigation Buoys?

Our ZAZ steel buoys are made of steel construction and have excellent stability characteristics. All ZAZ Marine Steel buoys are made following IALA guidelines.

All navigation buoys are successfully being used to demarcate a variety of marine and coastal areas, such as waterways, marinas, rivers, port entrances, ocean and offshore locations.

Their high shock resistance and stability characterize them. Metallic parts of the buoys (superstructure and tail) are made from hot-dip galvanized steel, and are designed to provide a long service life under harsh marine conditions. They can be customized under the client's request, as well as be made from stainless steel or marine aluminum.

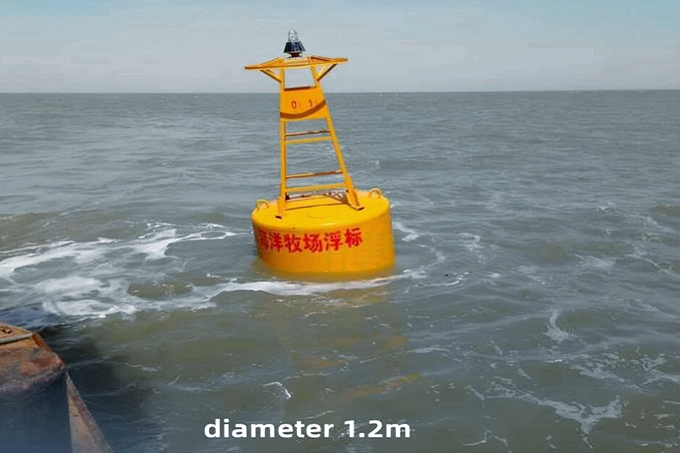

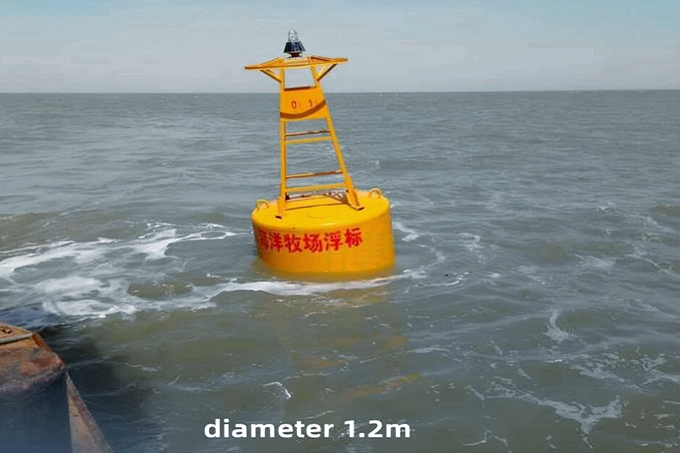

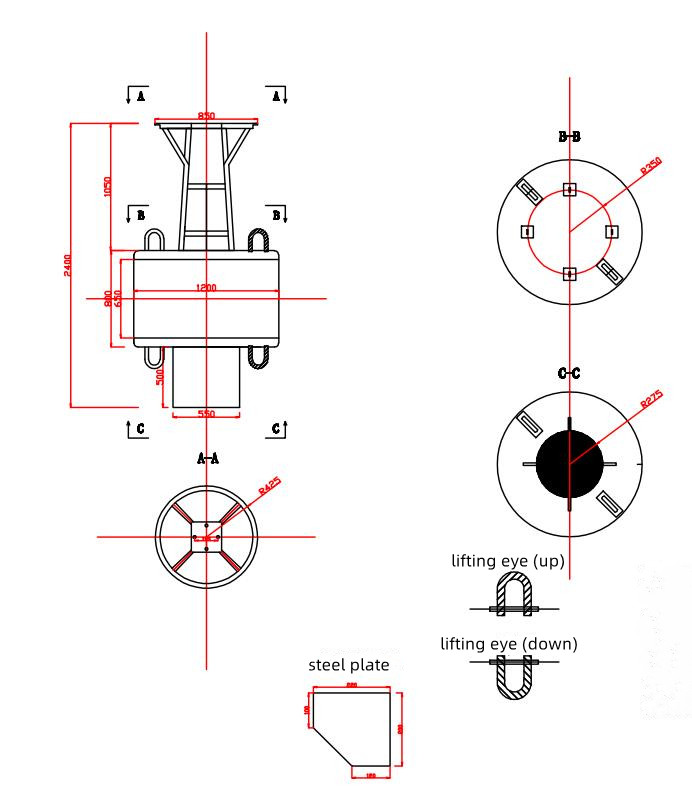

Specific Information About Our 1.2m Marine Navigation Buoy:

Brand: ZAZ

Diameter: 1200mm

Total height: 2400mm

Thickness of the plate: 6mm

Navigation draft:>1000mm

Total weight: 400kg

Wind resistance: >45m/s

Temperature range: -40~50℃

Anchor Chain diameter: ¢17.5mm

Sinker weight: 500kg~1000kg

Focal height: >3000mm

The height of freeboard: >700mm

Reserve buoyancy: 500kg

About Welding:

* We use CO2 welding, manual welding, Submerged arc auto welding, and automatic welding.

*All weld surfaces should be visually inspected, the weld wave should be uniform, and the edges of the weld should be smoothly transitioned to the base metal,

The shape and size of the weld should meet the requirements of the drawing, and the surface of the weld shall not have cracks, slag, unfused, porosity, weld tumors, or arc pits;

*We use ultrasonic flaw detection technique to complete the welding testing.

About Painting:

* We use epoxy paint.

*Shot peening pretreatment will be the first step, and then we will paint the anticorrosive paint within 4 hours after pretreatment.

*We use high-pressure airless spraying as much as possible.

* For the parts that are difficult to spray, such as welding lines and frame edges, we usually brush one or two layers before formal coating.

Pictures of Our Workshop:

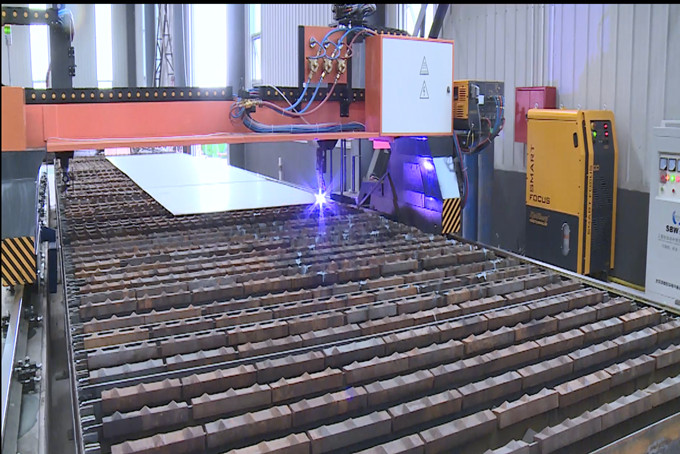

Pictures of Our Processing Equipment:

If you want to know more information about our steel navigation buoys, please send us an inquiry or an e-mail, and we will respond to you within 24 hours.

Please Feel free to send your inquiry in the form below. We will reply you in 24 hours.