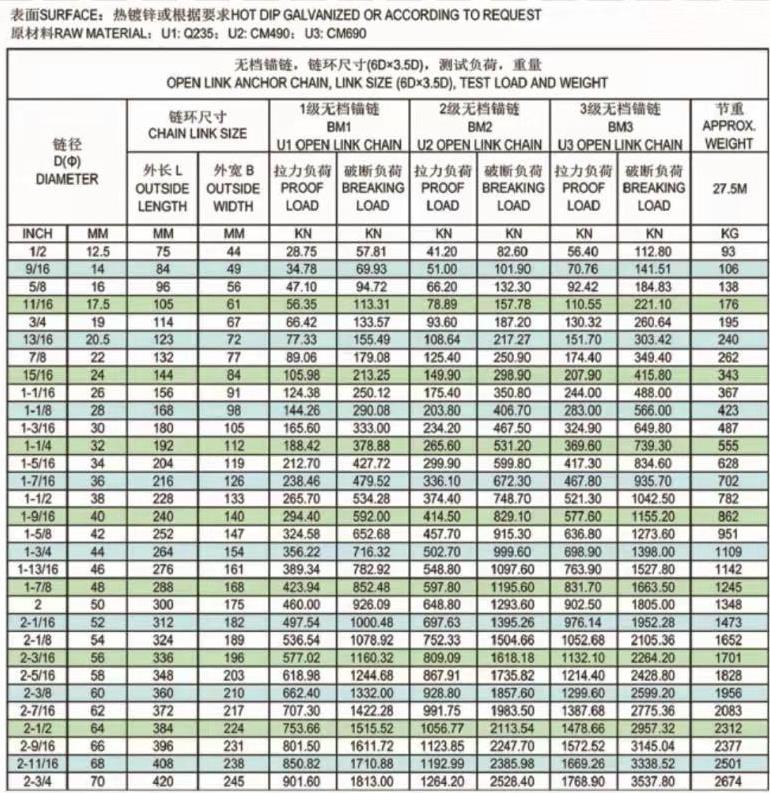

Studless link chain is made of metal and the chain diameter starts from 12.5MM to 162mm.

Material: Hot-rolled anchor steel, CM490, CM690, stainless steel 316, 316L

Grade: U2, U3

Chain Diameter: 12.5mm to 70mm

Studless link chain with primary color, black painted anchor chain and galvanized anchor chain are available for clients.

Here are some basic information about studless link chain:

* Technical requirement.

1,The material of anchor chain and its accessories.

1) The material of anchor chain and its accessories should use marine anchor chain steel which is above CM490 specified in GB/T 18669.

2) The surface quality, dimensional deviation, chemical composition, mechanical properties and process properties of the materials used for anchor chains and accessories shall comply with the relevant provisions of GB/T 18669.

3) The round steel manufacturing anchor chain and accessories shall be checked by the anchor chain manufacturing plant whether its mark is consistent with the items listed in the certificate, and check whether the surface quality, dimensional deviation, chemical composition, mechanical properties and process properties of the round steel comply with the provisions of GB/T18669.

4) links in the same link should be made of the same grade material.

2,The technology of anchor chain and accessories.

1) The link shall not be welded by hand, and the link with a diameter greater than 26mm shall be manufactured by flash butt welding or other welding methods approved by the inspection agency.

2) The joining shackles, end shackles and swivels should be forged.

3, The surface quality.

1) The surface of the link and accessory shall not have cracks, delamination and other defects affecting the quality, and shall not obstruct the fit and relative rotation of the parts, as well as changes in the size of the link.

2) The welding area of the link should be welded thoroughly, and there should be no defects such as porosity, overburning, slag clamping, etc.

3) Small surface defects can be eliminated by sanding, but the diameter of the polished chain link should be within its tolerance, and the polished part should transition smoothly with the surrounding surface, and the grinding depth away from the chain crown part is allowed to be relaxed, but not more than 5% of the chain diameter.

4) Links and accessories are painted in accordance with GB/T 533 after the completion of tests and inspections.

4, Heat treatment.

1) After welding, the entire section of anchor chain and accessories should be normalized or normalized and tempered or quenched and tempered to eliminate internal stress and ensure mechanical properties of heat treatment.

2) The heat treatment of the anchor chain should be carried out before the tensile test and the pull test.

3) All specimens should be heat treated with the same process as the anchor chain they represent.

4) The heat treatment of the accessory should adopt the heat treatment method of the same level of anchor chain.

Please Feel free to send your inquiry in the form below. We will reply you in 24 hours.